The National Circular Plastics Standard Explained: Part 2

In the first part of this series, we highlighted the basis of the National Circular Plastics Standard, also known as the admixture obligation, and the purpose of this groundbreaking regulation in the Netherlands. Now, we dive deeper into its sustainable and economic impact. Crucial questions take centre stage: do these standards make plastic products more expensive? And what does this mean for the position of Dutch companies in the European market?

Brief Recap: The National Circular Plastics Standard

- Purpose of the Standard: The National Circular Plastics Standard sets specific requirements for the percentage of reuse (recyclate) and renewable (biobased) materials in plastic products. With the aim of promoting a circular economy in the plastics industry through the use of more sustainable materials and processes.

- Definition of recyclate: Recyclate is material extracted from recycled plastics. It includes materials recovered from both consumer and industrial waste streams. However, there is ambiguity about what exactly is included in the definition of recyclate. It is clear that post-consumer materials are included, but the status of post-industrial materials remains uncertain.

- Role of converters: Converters, the companies that transform polymers into plastic products, play a crucial role in meeting the standard by integrating recyclate and biobased materials into their production processes.

- Trade register for renewable polymer units: Renewable polymer units are a measure of the amount of bio-based or recycled polymers used in products. The trade register is a mechanism to record and promote the use of renewable polymers in production.

Is The National Circular Plastics Standard Feasible?

The National Circular Plastics Standard sets ambitious targets for both mechanical and chemical recycling, as well as for the production of biobased materials. The feasibility of this standard is influenced by several factors, in particular the current capacity and development of biobased production.

Currently, the production of biobased materials is in its early stages, with less than 1% of total production. This low production rate poses a significant challenge to achieving the set targets of the standard. To achieve the ambitious 30% target, it is essential that a significant part of this standard is fulfilled by bio-based production. This is because it is estimated that recycling processes, both mechanical and chemical, can only contribute up to 25% towards achieving this standard.

Scaling up biobased production is therefore crucial and can be achieved in several ways. One option is the import of biobased materials, which could provide an immediate, yet temporary, solution. A more sustainable solution would be the development of a new biobased factory in the Netherlands, which would lead to a more autonomous and controllable production capacity. For stimulating this development, subsidies could play a key role, by lowering the financial barriers to investment in biobased production technologies.

In light of these factors, it is clear that achieving the standard will require a combination of technical innovation, policy support and market development. The successful implementation of the standard will depend not only on technical feasibility, but also on the willingness of industry and government to invest in and support the transition to more sustainable production methods.

What Does the National Standard for Circular Plastics Offer?

At the heart of the transition to a circular economy lies the principle of closing the resource cycle. One of the current challenges in the market context is the lack of incentives to phase out the use of primary fossil plastics. The National Circular Plastics Standard is part of the Netherlands’ ambitious target to reduce CO2 emissions by 60% by 2030, which requires a significant reduction in the use of fossil raw materials. However, this effort is complicated by the lack of European approval for a tax on virgin materials, possibly influenced by the lobbying of plastic producers. This context of both national ambition and European policy dynamics forms the background against which the environmental impact of the Circular Plastics Standard is evaluated.

Objectives

The government’s circular plastics policy plays a central role in the transition, the Dutch government has set ambitious targets for making plastics circular. This policy focuses on two main areas:

1. Reduction and prevention: Despite the advantages of plastics, such as efficiency, versatility, affordability, and strong material characteristics, the aim is to reduce or prevent the use of plastics that are difficult to recycle or are used once. This includes plastics with a mixed composition that makes recycling difficult or impossible.

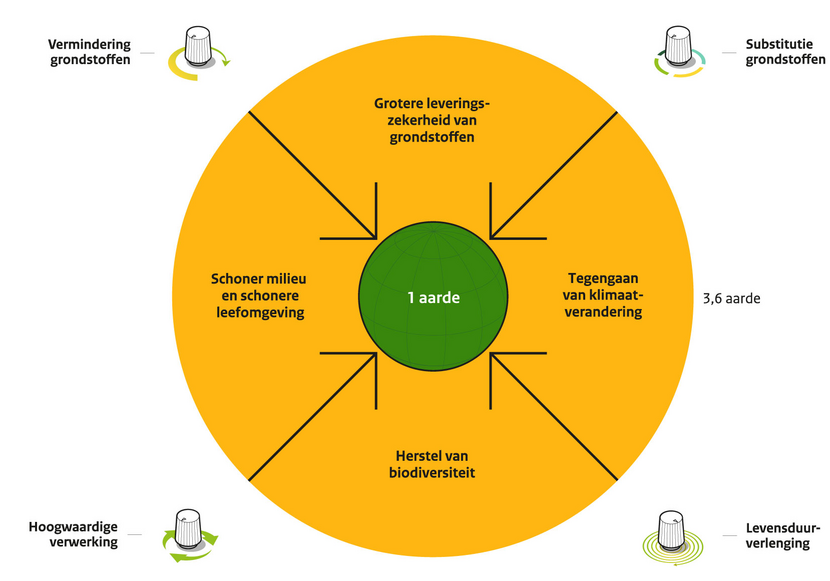

2. Sustainability: The focus is on making plastics sustainable throughout their life cycle. This includes the use of sustainable raw materials, minimising raw material use (‘narrow the loop’), maximising the lifespan of products and raw materials (‘slow the loop’), and high-quality reuse of materials (‘close the loop’).

Overview of what a circular economy can look like. Source: Rijksoverheid.

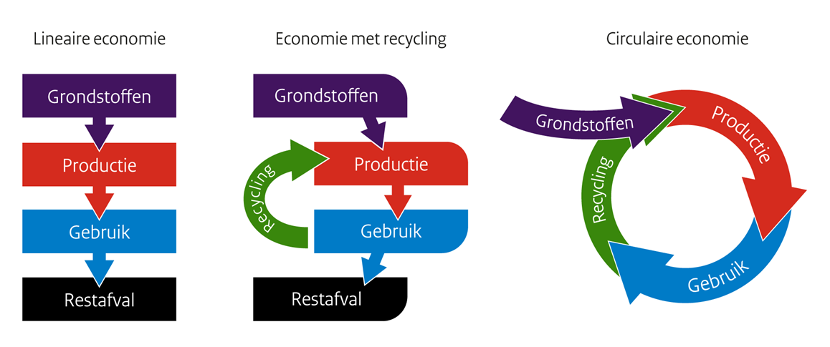

Possible scenario plastic chain. Source: Transitieagenda Kunststoffen.

Acceleration of Circular Plastic Chains

As part of the transition to a circular economy, accelerating circular plastic chains is crucial. This approach focuses on reducing dependence on fossil raw materials and increasing the use of more sustainable alternatives such as recyclate and bio-based plastics. Key aspects at a glance:

- Replacing fossil plastic: A core strategy is to replace fossil plastic with recyclate or bio-based plastic, which contributes significantly to reducing CO2 emissions.

- Targets: The goal is to achieve 700 ktonnes of CO2 reduction per year from 2030, as a step towards meeting both national and international environmental commitments.

- Standardisation and incentives: The government has set standards for the use of recyclate and bio-based plastics, and supports companies in meeting these requirements.

- Additional measures: These include measures to reduce waste incineration of plastics and increase CO2 charges.

Potential Constraints

- Import of Virgin Plastic: There is a risk that Dutch consumers and companies will buy more virgin plastic products from abroad, which could undermine the effectiveness of the standard.

- Procurement of Recyclate by Dutch Converters: Another challenge is the possible procurement of recyclate from abroad by Dutch companies, which may limit the intended environmental impact.

- Dependence on European Policy: The effectiveness of the National Circular Plastics Standard depends on the additional effect compared to existing European policy. At a 30% standard, part of which may be biobased (22% recyclate, 8% biobased), the maximum CO2 gain could be 400 ktonnes under European obligations.

Economic Effects

Converters cannot always use recyclate because their production processes are usually tailored to specific raw materials. Not every type of recyclate is suitable for every production process, especially when strict requirements apply, such as food packaging. It is therefore necessary to establish a trade register. This register will allow certificates for renewable polymers to be traded, allowing companies to purchase the right recyclate and bio-based raw materials that fit their production processes and specifications. This contributes to the implementation of the National Circular Plastics Standard.

To implement this, CE Delft draws a clever comparison with the NEa Energy Register for Transport, which acts as a trade register for renewable fuels (HBEs), for plastics these could become Renewable Polymer Units (HPEs). These represent the proportion of recycled plastic, biobased plastic, or a combination thereof.

Impact on the Market

1. Customer choices: Due to the increase in cost price, customers of plastic products, such as car manufacturers, electronics manufacturers and food producers, may choose to source their products abroad rather than in the Netherlands.

2. International market: The international plastic market has significant import and export flows, indicating a global influence and interdependence of different countries in this sector. However, due to the lack of precise quantitative data, the exact size and full implications of these trade flows are difficult to determine.

3. Production losses and leakage effects: An increase in the cost price for Dutch converters may lead to production losses in the Netherlands and a shift of production abroad.

Leveling the Playing Field

Within the frameworks of the National Circular Plastics Standard, equal opportunities and shared responsibilities are a fundamental aspect. This approach aims to promote a fair and sustainable market within the plastics industry, with the crucial elements being:

1. Strengthening Fair Competition:

To ensure fair competition, unambiguous standards are implemented to ensure that all companies, regardless of size, comply with the same environmental standards. This approach promotes innovation as a necessity, encouraging all players to explore and implement sustainable solutions.

2. Cooperation at International Level:

In seeking cooperation at the international level, harmonisation with EU standards is pursued, ensuring that Dutch standards are in line with European directives. Moreover, the Netherlands can play a leading role in global sustainability initiatives, contributing to the setting of global standards for sustainability.

3. Specific Support for Small and Medium-sized Enterprises (SMEs):

With a view to supporting SMEs, access to resources is ensured so that SMEs are not left behind in the transition to sustainability. In addition, this approach helps maintain a balance in the market, which is essential for ensuring a diverse and competitive business landscape.

4. Increased Transparency:

To increase transparency, clear communication is sought regarding regulations and expectations for all market participants. Effective enforcement is crucial here, as it ensures compliance with established standards and supports confidence in the market.

Dynamics around the Standard

We also need to consider other factors. One of the crucial questions that arise when implementing the National Circular Plastics Standard is its scope. It is currently unclear whether all polymers, including rubber, adhesives, sealants, paints and coatings, are covered by the standard. Although the standard’s approach is aimed at all sectors, it remains uncertain whether there will be exceptions. This lack of clarity creates challenges for companies in preparing for and complying with the standard.

The impact of political changes, especially regarding the new cabinet, is another important aspect. The regulation could have a major impact on recyclers and the wider industry. Depending on political direction and priorities, changes or refinements may be made to the standard, which is crucial for the companies involved.

The government has introduced several incentives to support companies in switching to non-fossil plastics. These measures are essential for accelerating this transition:

Financial support: €69 million has been allocated under the Spring Budget 2024, with a total of €269 million aimed at 2030. These funds are intended to facilitate and accelerate the implementation of the standard.

Individual business support: Besides financial support, there is also a focus on individual support to companies in adapting to the new standard.

Joint research: There is an emphasis on joint research to develop innovative solutions and strategies for achieving the goals of the standard.

Investment grants: Grants intended to encourage companies to invest in technologies and processes that contribute to the circular economy and reduce dependence on fossil resources.

In Brief

The National Circular Plastics Standard has the potential to significantly impact both the industry and the environment. While there are challenges, such as feasibility and economic impact, the standard also offers opportunities for innovation and sustainability. The Dutch plastics industry is on the verge of a major transition, where this standard will play a crucial role in both national and European contexts.

This blog post was composed based on information from the reports National Goal Plastics Standardisation and Mandatory share of recyclate or biobased in plastics from CE Delft, and information from Martijn Reubzaet’s presentation, from the Ministry of Infrastructure & Water Management, at the National Plastics Congress 2023.