Developing future proof plastic packaging

In a world where plastic packaging paints our surroundings, the call for sustainability echoes louder than ever. This reality is both a stark reminder of the challenges we face and a motivator to explore untapped opportunities for change.

In the following post, we explore the versatility of plastic packaging and underscore the necessity for ‘future-proofing’. We delve into the intertwined roles of the circular economy and consumer behaviour in shaping a sustainable packaging future. We also shed light on our holistic strategy for revolutionising plastic packaging, informed by globally recognized experts in this field.

Join us as we navigate this journey of transformation, charting a course towards a future where plastic packaging is as gentle on our planet as it is functional in our lives.

Unpacking the World of Plastic Packaging

Our modern world is flooded with plastic packaging. The chameleon-like nature of plastic packaging allows it to slip seamlessly into our daily lives in several ways. It’s the tough protector encasing our electronics, the flexible guard maintaining our food’s freshness, and the thermal regulator keeping our drinks at an ideal temperature. Its benefits are far-reaching. By being lightweight, it minimises transportation costs and carbon emissions. Its resilience ensures product safety during transit and helps reduce waste. Notably, also plastic’s ability to prolong product shelf life is a key ally in combating the global issue of food waste.

The Changing Tides

Plastic bottle recyling deposit system. Source: Alamy.

In the context of plastic packaging, what does future proof mean? Future-proofing means taking steps to ensure that our actions today do not limit the options of future generations. To achieve this something needs to change, and at the heart of this change lies the circular economy and consumer behaviour.

A circular economy aims to minimise waste and make the most of resources. It involves ensuring that all packaging materials can be reused, refilled, or recycled back into the system. This strategy significantly reduces the need for virgin plastic, making packaging a truly circular resource.

Consumer behaviour, on the other hand, focuses on encouraging the end-user, the consumers, to adopt sustainable practices. This includes making conscious choices such as opting for packaging made from less plastic or recyclable materials, properly disposing of packaging, and actively participating in the circular economy. An example of this is refill and reuse packaging, where consumers are encouraged to use refillable containers when purchasing specific products or returning packaging for reuse, as seen in the PET bottle deposit system. Both these elements play pivotal roles in developing future-proof plastic packaging.

Our Approach to the Future

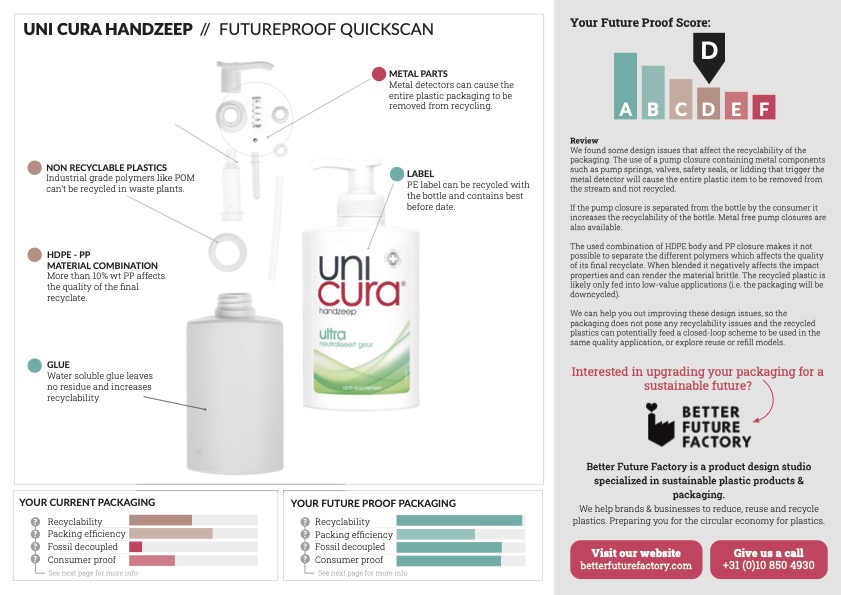

In our pursuit of developing future-proof plastic packaging, our focus lies on achieving significant advancements in making disposable packages recyclable, prioritising the principles of reuse and refill. Additionally, we have identified four key pillars that play a vital role in our future approach as well:

1. Recyclability

Packaging must not only be made from recycled material but must also be capable of being recycled after use. This not only reduces packaging waste but aligns with the model of a circular economy.

2. Packaging Efficiency

By improving efficiency, we aim to reduce the amount of packaging material used per product. This strategy not only reduces waste but also has positive effects on the environment. This approach can also reduce food waste by enhancing packaging designs to preserve food better.

3. Fossil Decoupled

To genuinely future-proof our plastic packaging, we must transition away from fossil-based plastics, exploring alternatives like bio-based plastics that offer similar functionality with lesser environmental impact.

4. Consumer Proof

Future-proof packaging must be consumer-friendly. Consumers are more likely to correctly dispose of packaging that is easy to separate and recycle. Educating consumers about sustainable disposal is also a critical part of this pillar.

Example of Future Proof packaging Quickscan by Better Future Factory.

Grounding Our Work in Expert Principles and Guidelines

Five perspectives on sustainable packaging model. Source: KIDV.

Our approach to future-proofing plastic packaging is not made in isolation. Instead, it is based on extensive research, established guidelines, and pioneering work of several leading organisations in the field.

The Dutch Kennisinstituut Duurzaam Verpakken (KIDV) is one significant influence. The organisation provides knowledge and guidance about sustainable packaging. Their guidelines, which encompass everything from design principles to material utilisation, have become a standard to strive towards in the packaging industry. By aligning our practices with KIDV’s guidelines, we ensure that we meet the highest standards of environmental consideration.

The Ellen MacArthur Foundation, a thought leader in circular economy principles, is another powerful influence in shaping our approach. The foundation’s goal of eliminating waste and continuously reusing resources resonates strongly with our own, and provides crucial insights that we’ve incorporated into our strategies.

Lastly, RecyClass is a comprehensive tool that helps us in measuring the practical recyclability of our packaging. By adhering to their standards, we can ensure our packaging is not just recyclable in theory, but in practice as well, and can indeed be reintegrated into the economy, thereby truly aligning with the principles of a circular economy.

Putting Theory Into Practice: Some Examples of Our Work

At Better Future Factory, we believe in walking the talk. Some examples of our commitment to future-proof plastic packaging materials into our projects are the following:

Packback

Together with Packback, we took on the challenge to embody future proof plastic packaging by creating a reusable packaging solution for home deliveries. By replacing single-use plastics, it helps combat plastic pollution. Each Packback package is designed for repeated use servicing many in many loops, and at its life’s end, it can be fully recycled. Furthermore, the packaging material, a food-safe, bio-based polypropylene, is derived from renewable feedstock, ensuring it’s sustainable and recyclable.

Packback project by Better Future Factory.

Erno Laszlo project by Better Future Factory.

Erno Laszlo

The Erno Laszlo plastic strategy also examplifies future-proof packaging. Tasked with balancing sustainability and a 100-year brand legacy, we began with a plastic scan to highlight areas for improvement, including potential virgin-to-recycled plastic substitution. In collaboration with the Erno Laszlo team, we developed strategies tuned to the circular plastic economy. This joint effort led to a promising, sustainable packaging strategy that respects both the brand’s heritage and our shared sustainable future vision.

HUM

Another example of plastic packaging fit for the future is HUM. Recognizing their customers’ growing environmental consciousness, they sought to enhance sustainability across their packaging portfolio. Using a plastic scan, we charted a path towards achieving 100% recyclability without compromising the brand’s prestigious image. The developed strategy illuminated opportunities to optimise packaging efficiency, substitute virgin materials with sustainable plastics, and gear up for the circular plastic economy. Consequently, HUM’s iconic bottle is now crafted from ocean-bound plastic, embodying the brand’s commitment to sustainability.

HUM project by Better Future Factory.

Final remark

As we stand at the crossroads of convenience and conservation, it’s clear that the narrative around plastic packaging and packaging waste is complex. It’s a story of significant benefits shadowed by substantial environmental and health concerns. Yet, amidst these challenges, there are emerging opportunities for innovation and change, positioning us on the precipice of a future where plastic packaging could be both convenient and conscious.